Overview

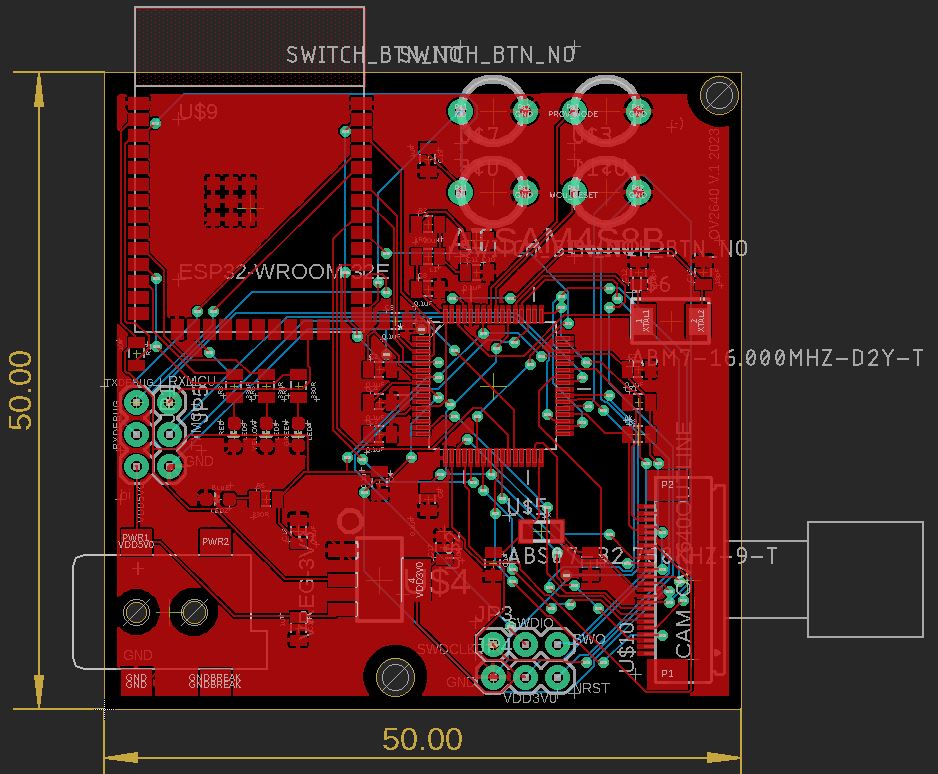

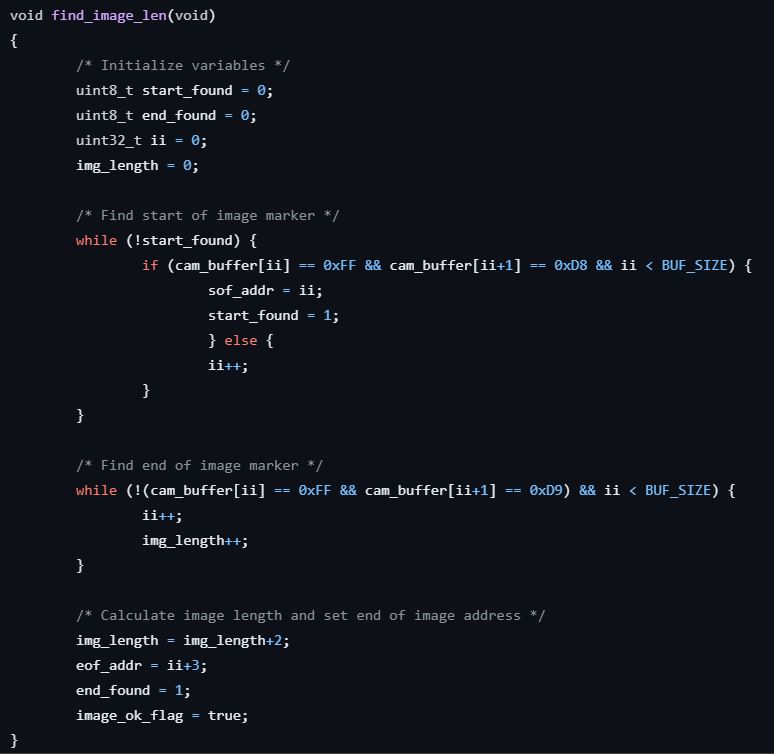

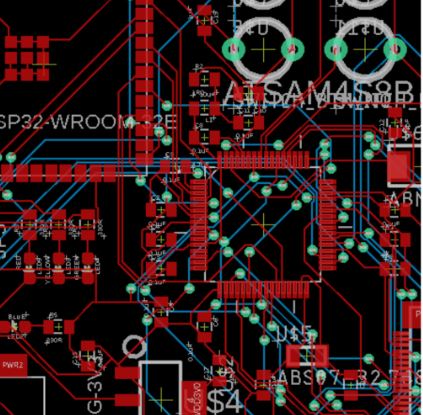

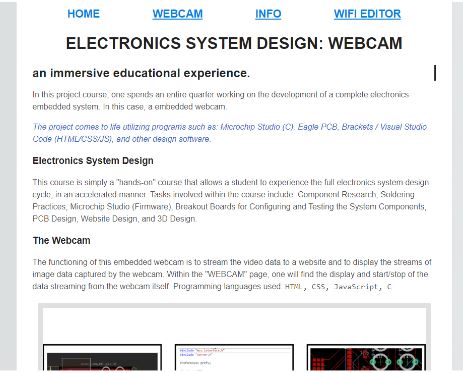

The webcam project involves a holistic approach to constructing a functional electronic system, with key components including the SAM4S8B microcontroller (MCU), ESP32 for WiFi connectivity, and the OV2640 camera acting as an image sensor. The interplay between these components is orchestrated through communication protocols such as I2C, SPI, and UART. The firmware, coded primarily in C, serves as the essential link between hardware elements, enabling them to function cohesively. The project transitions from prototyping on breadboards to utilizing development and breakout boards for individual components, facilitating focused configuration and programming. Following successful communication testing, the project progresses to a permanent state with the creation of a PCB board, serving as the physical foundation for component attachment and interconnection. The PCB design process involves defining pathways for connectivity, ensuring electrical links with power regulation, and optimizing the system's form factor. Once the PCB is manufactured, components are soldered onto the board, and additional considerations, such as 3D design and printing for housing, are addressed. The culmination is a fully realized electronic system capable of performing its designated function.